Laygo Template Library Setup Guide¶

This section describes how to construct microtemplates_dense library.

Introduction¶

The guideline provided in this section is not a golden flow; It is based on my (Woorham Bae’s) limited experience, so there must be better solutions. The intend is just to provide some tips that can reduce number of trials and errors I did. Just refer and do not rely!

- For now, Laygo does not support ‘path’ drawing, so please use ‘rectangle’ for all routings

- It is hard to get a perfect templates in your first trial. Don’t be frustrated if you cannot make it.

- Best idea is to refer microtemplates_dense library for other technologies if you can access to. But you need to understand some basics of template library before you replicate.

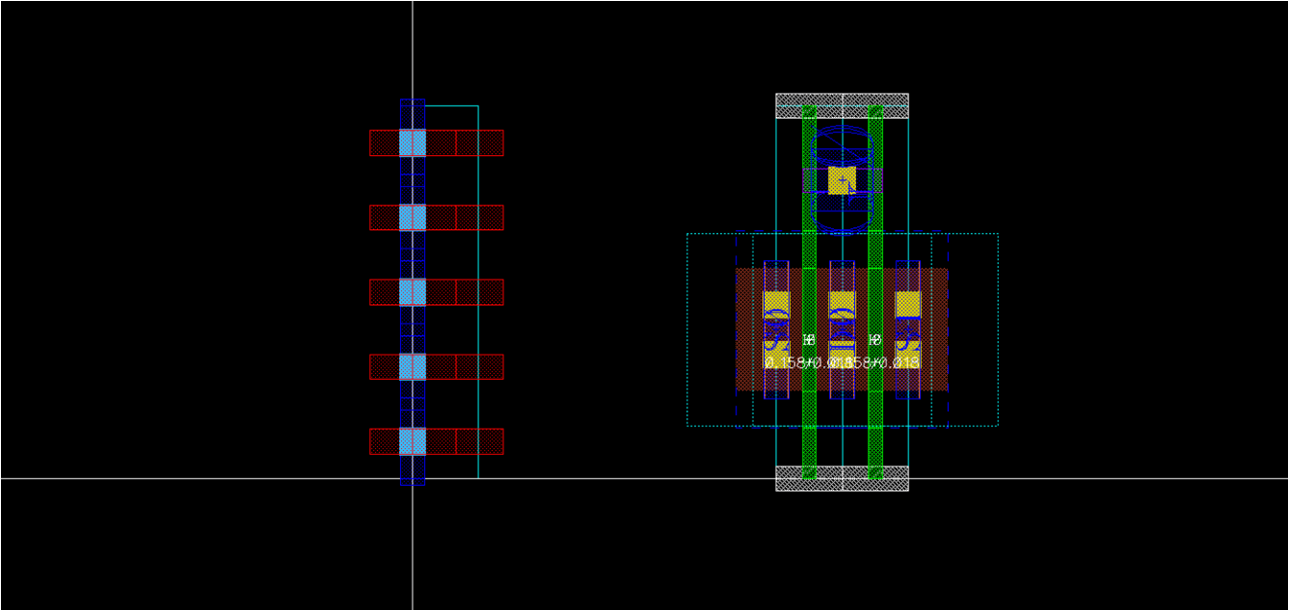

Let’s start with via(wire) template¶

Draw horizontal/vertical metals with minimum width

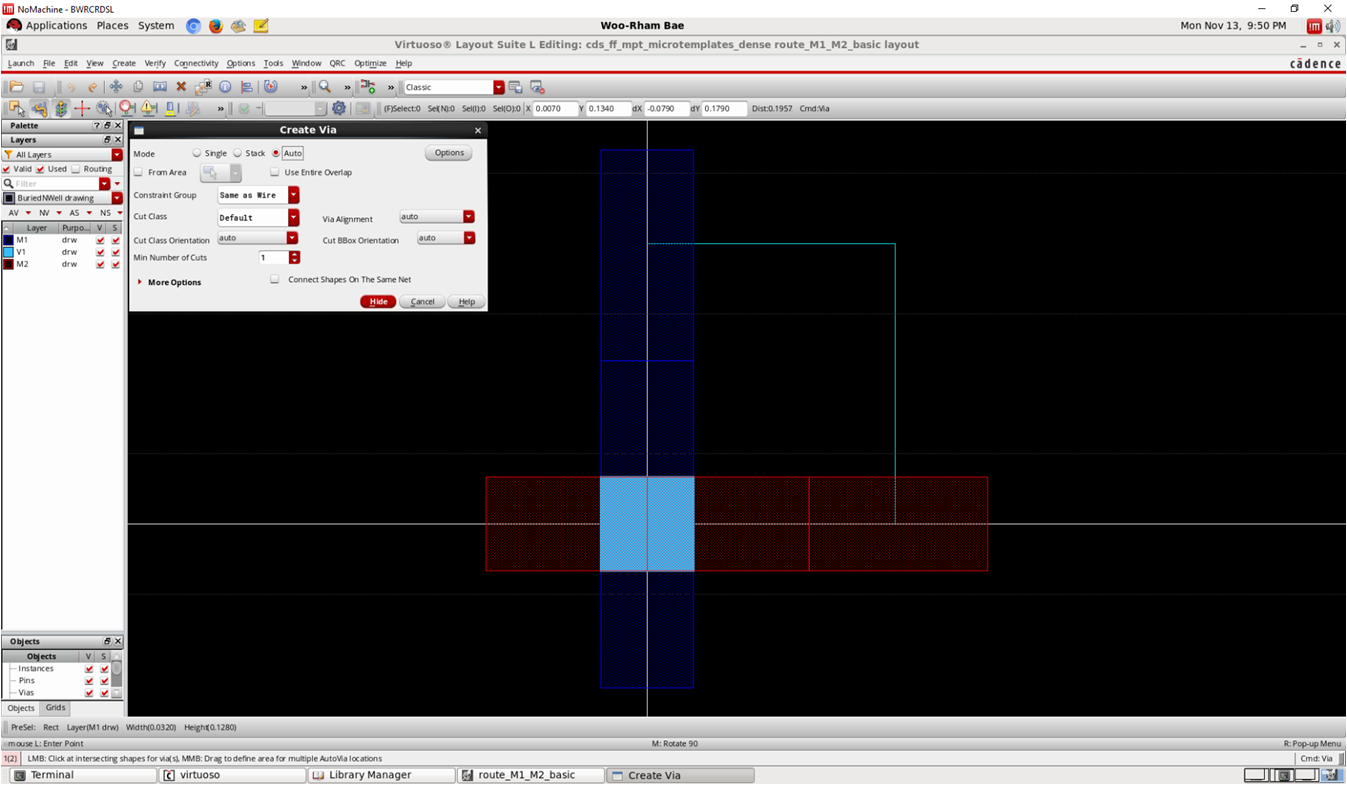

- Create => Via => Auto for creating via

template

templateMake the via object a separate instance

- Edit => Hierarchy => Make cell (ex. via_M1_M2_0)

template

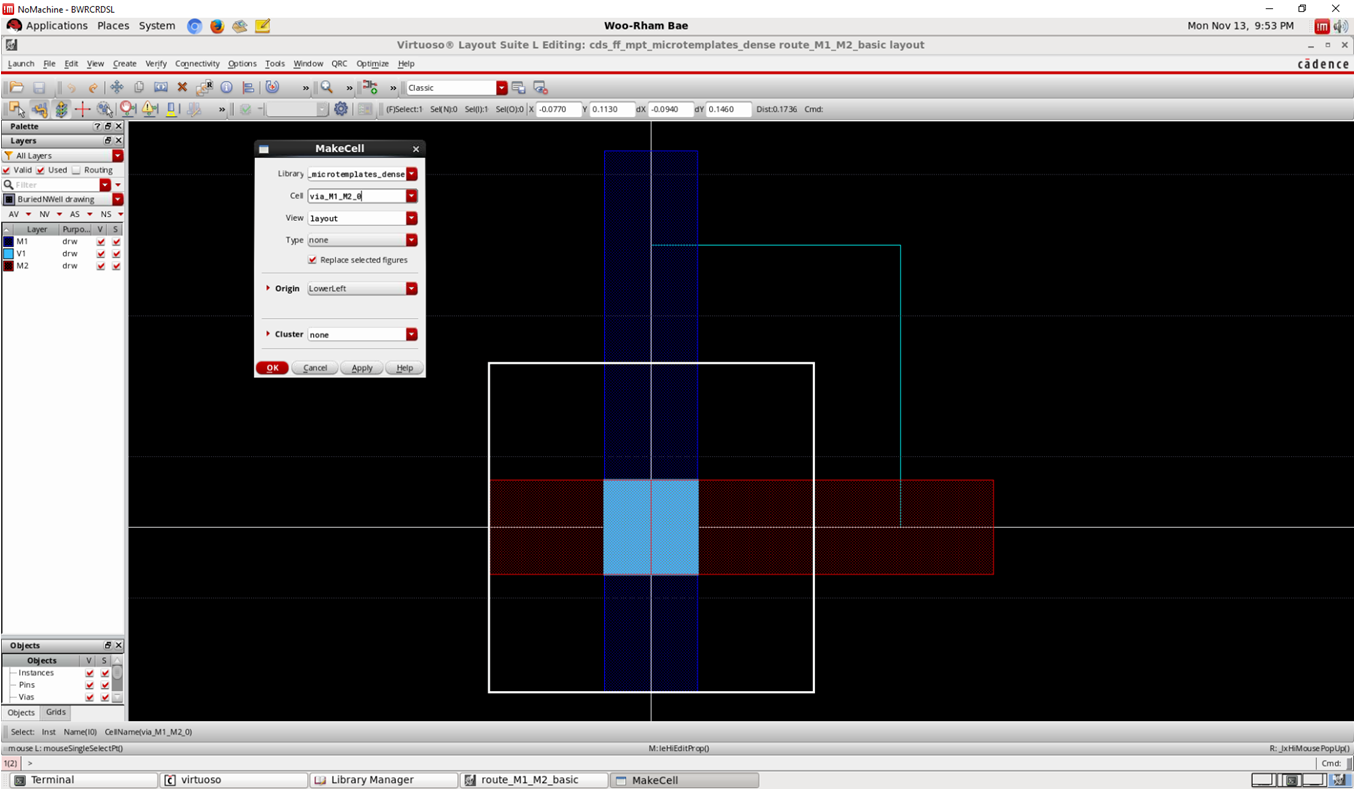

templateDraw other via templates

- There are various via templates for each layer

template

template

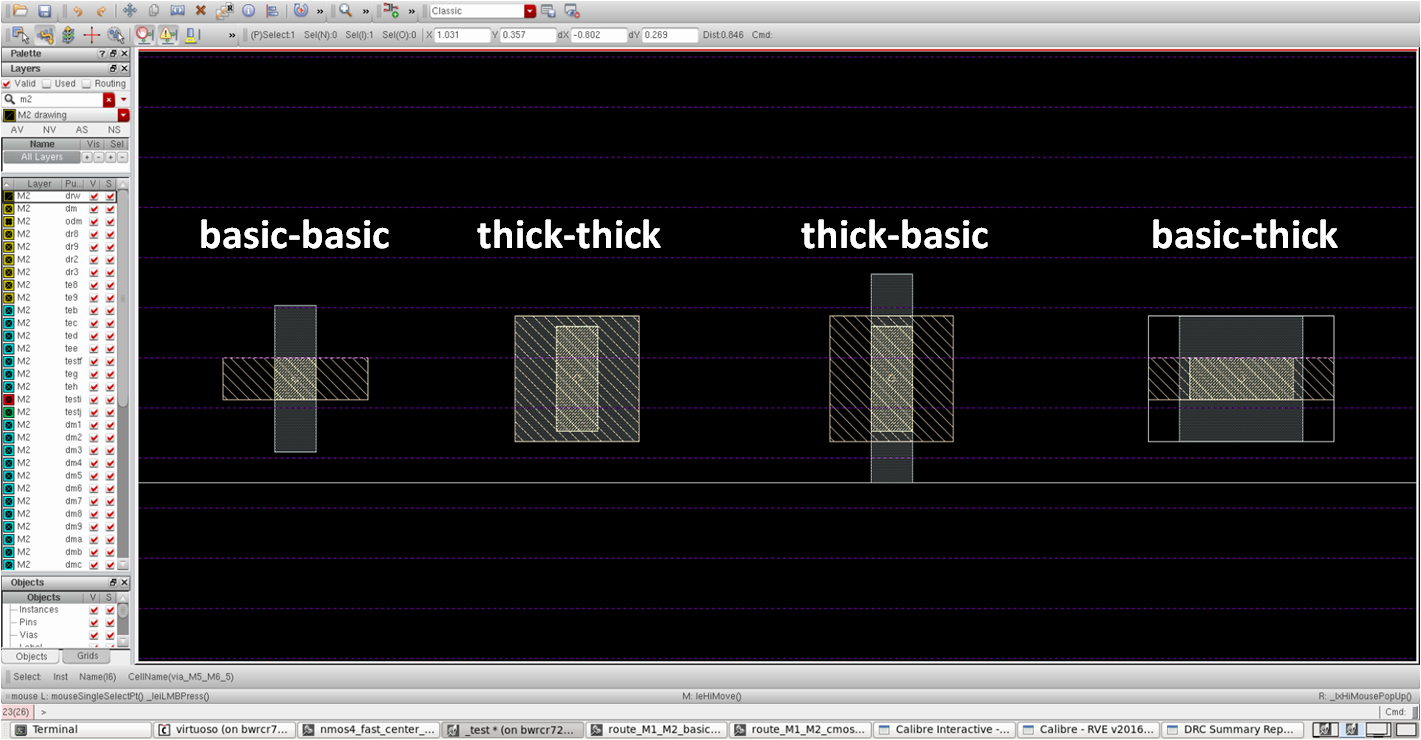

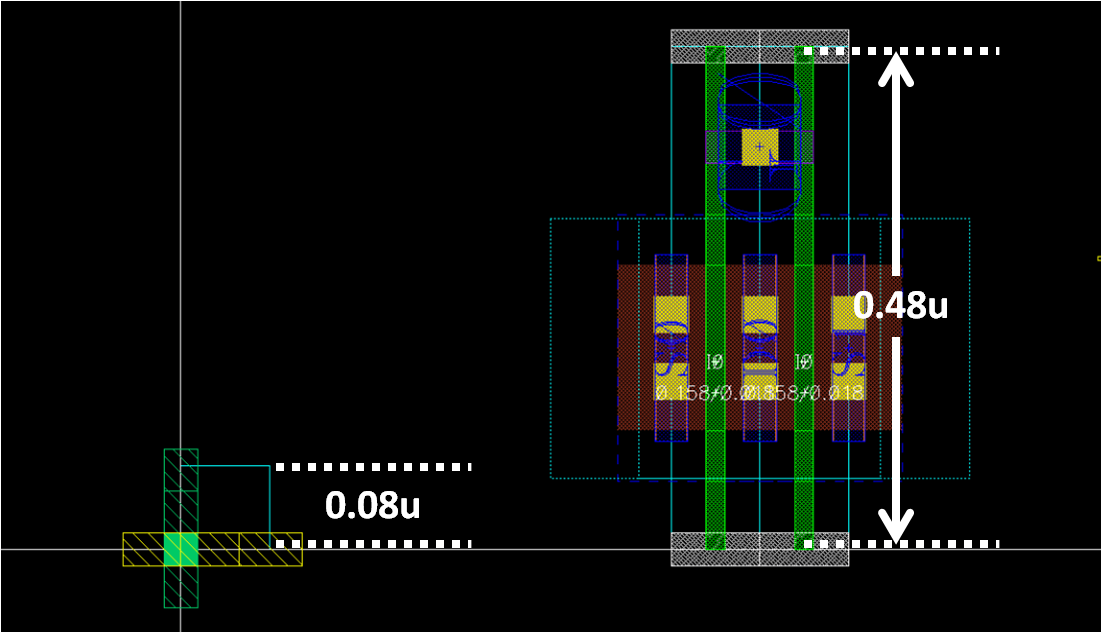

Transistor template¶

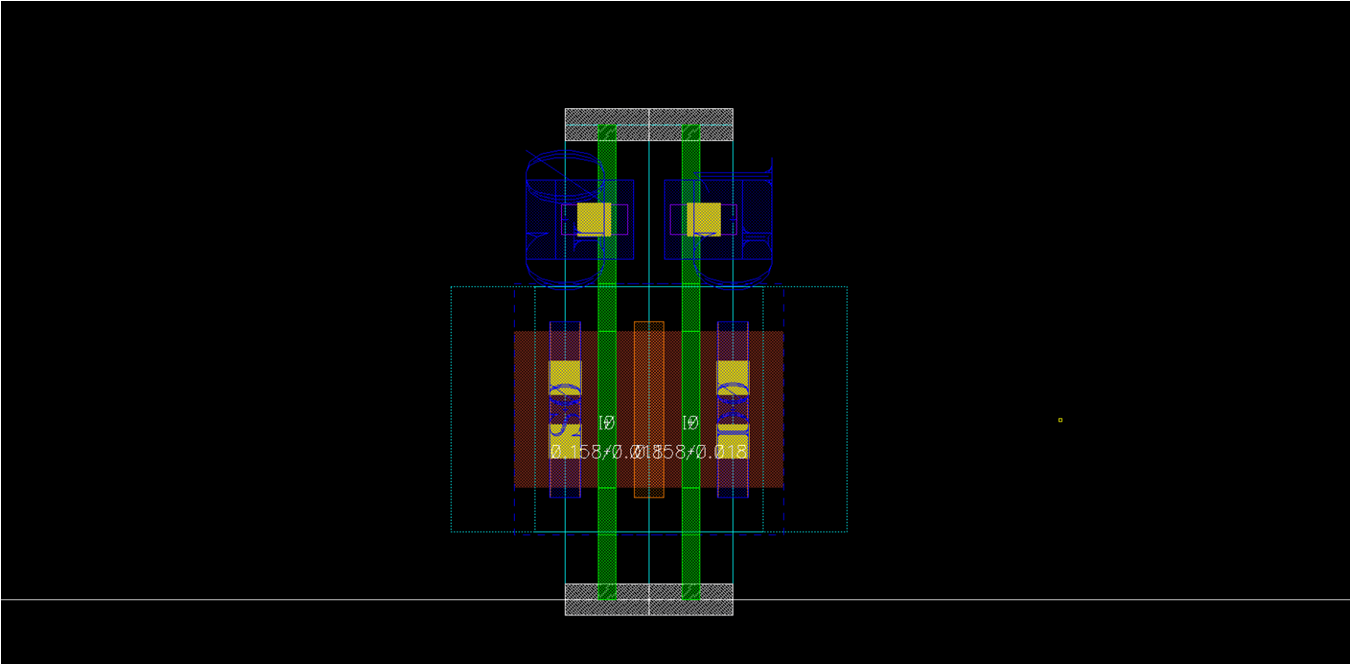

- Nmos4_fast_center_nf2: Most important templates!

template

template

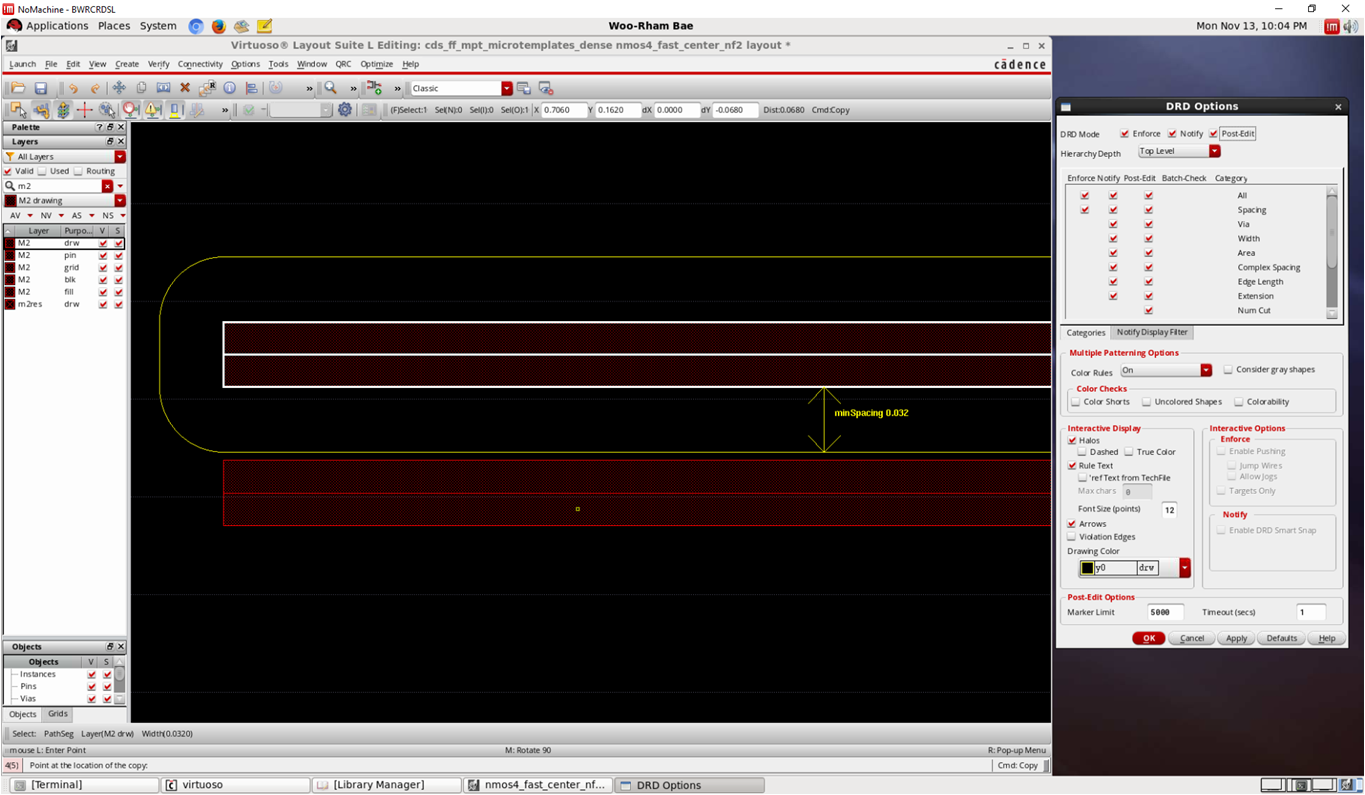

- Before placing an NMOS, we have to decide width (or number of fin) per finger

- Note that two M2 routing can be placed within S/D area

- Check M2 spacing rule

- With whatever you can do (Options => DRD Options => Enabling DRD Mode is useful)

template

template

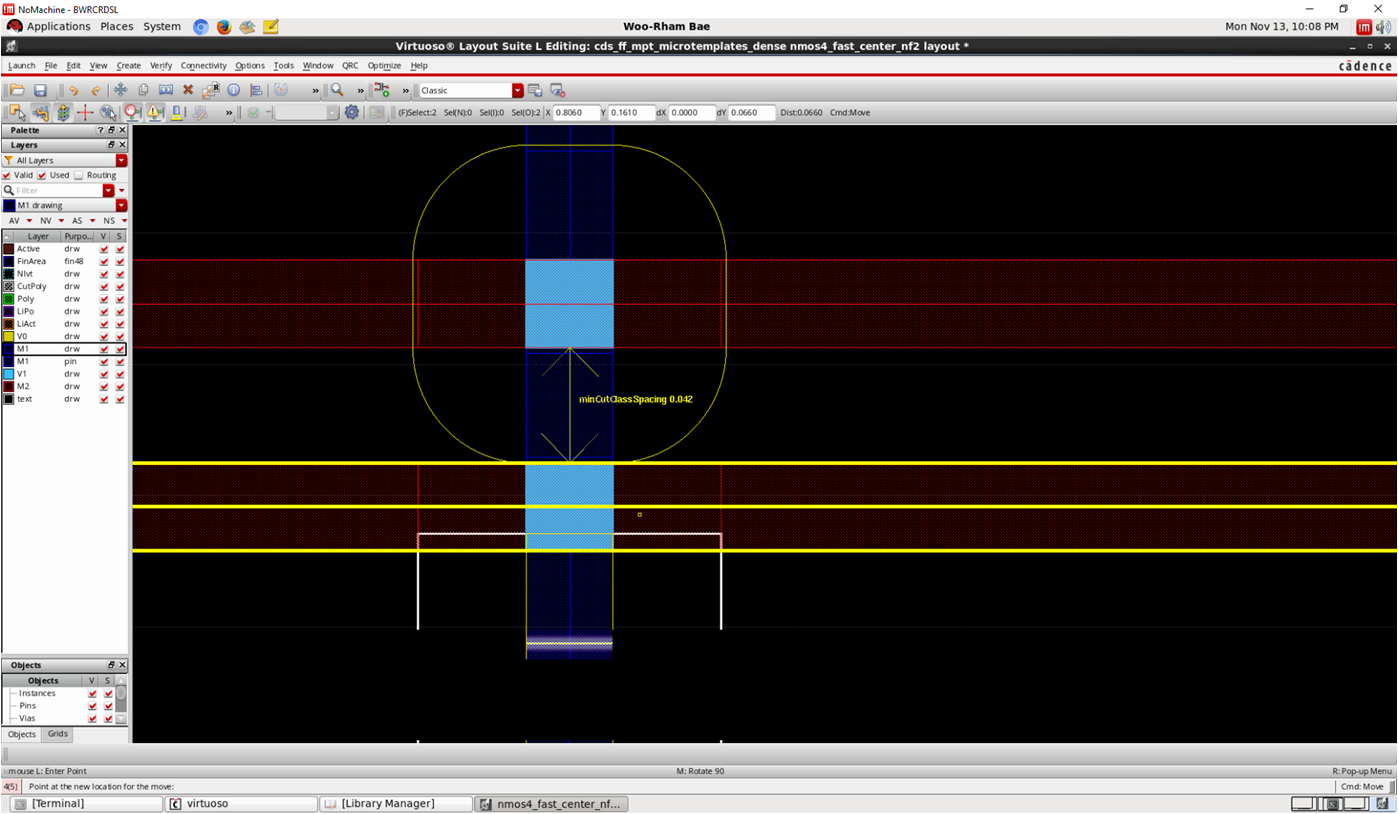

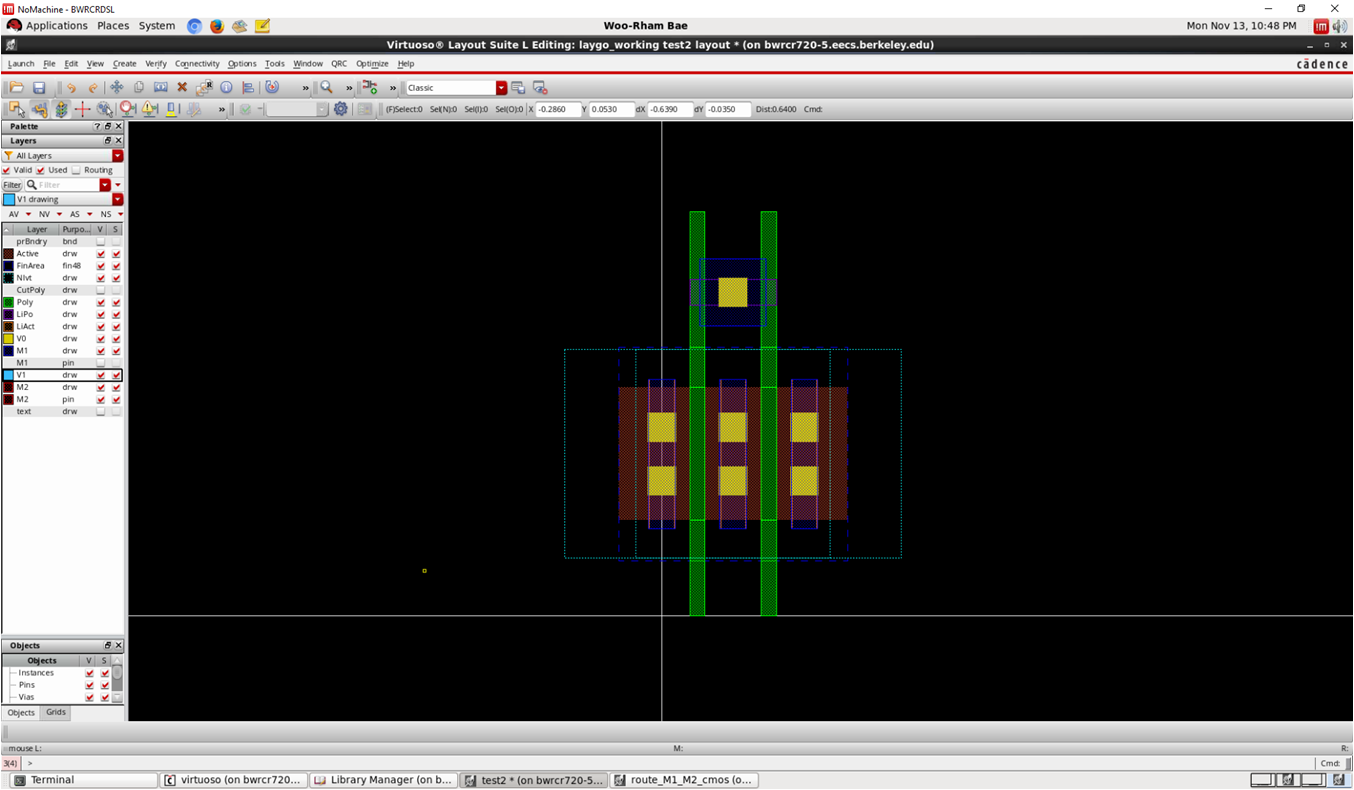

- Check V1 spacing rule as well

- Generally it is wider than M1 spacing

- It is not required, just suggested

template

template

- Choose number

- Choose a proper number of fins which is available to include two M2 routings/vias and place NMOS

- Turn off poly dummy options: it will be handled later

template

template

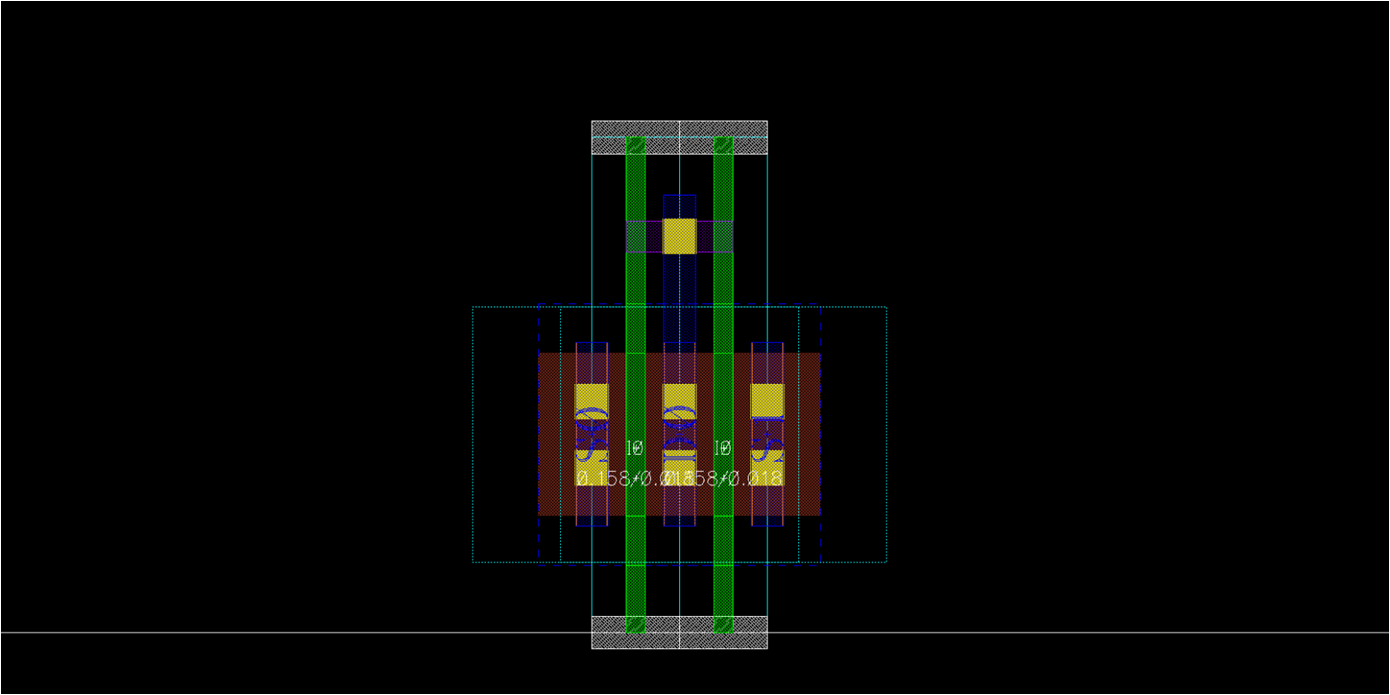

- Adjust coordinate of NMOS

- x: Center of left source should be at x=0

- y: Set intuitively(?). Consider a VSS rail will be placed at the bottom. We may modify it later.

template

template

- Draw gate contact

- One of the hardest part

- Best way is to refer standard cells

- You can activate poly connect option, but…

template

template

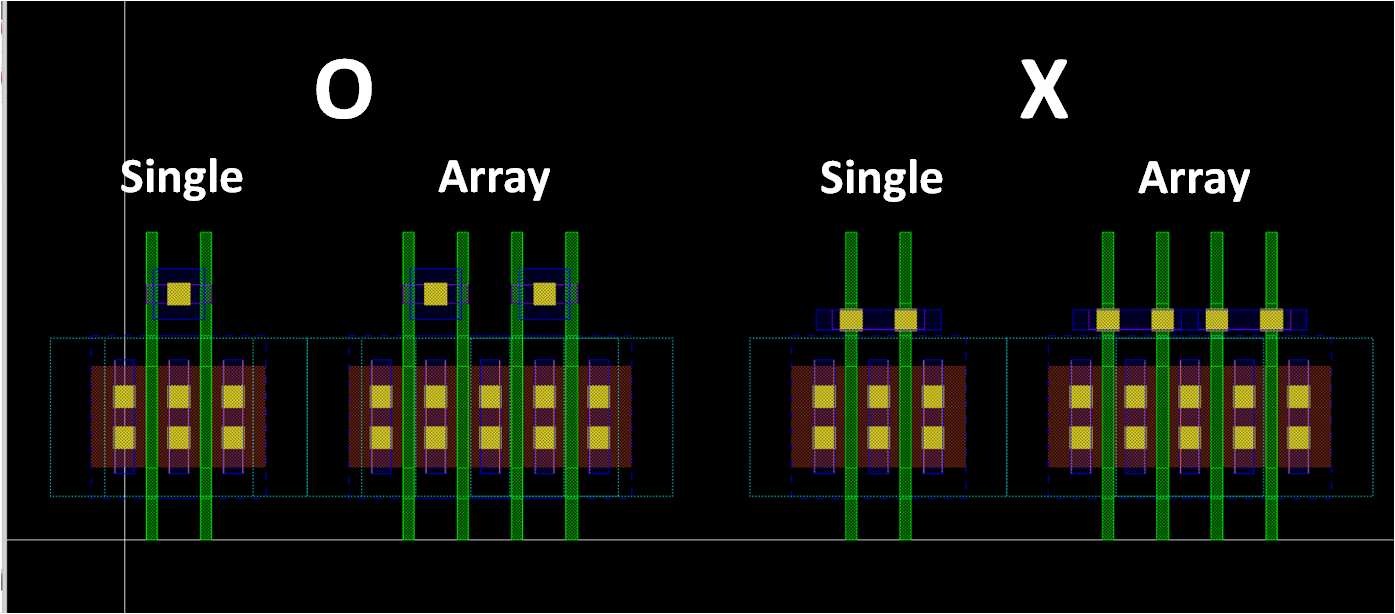

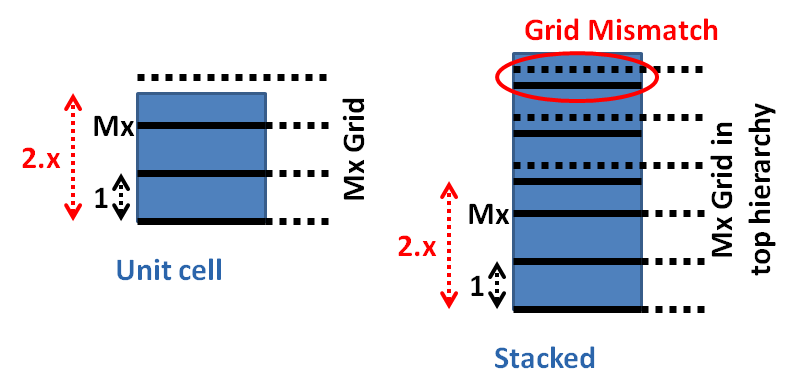

- Note that it will be placed in array

- If poly connect option gives a horizontally long M1 connection, you’d better to find an alternate way

template

template

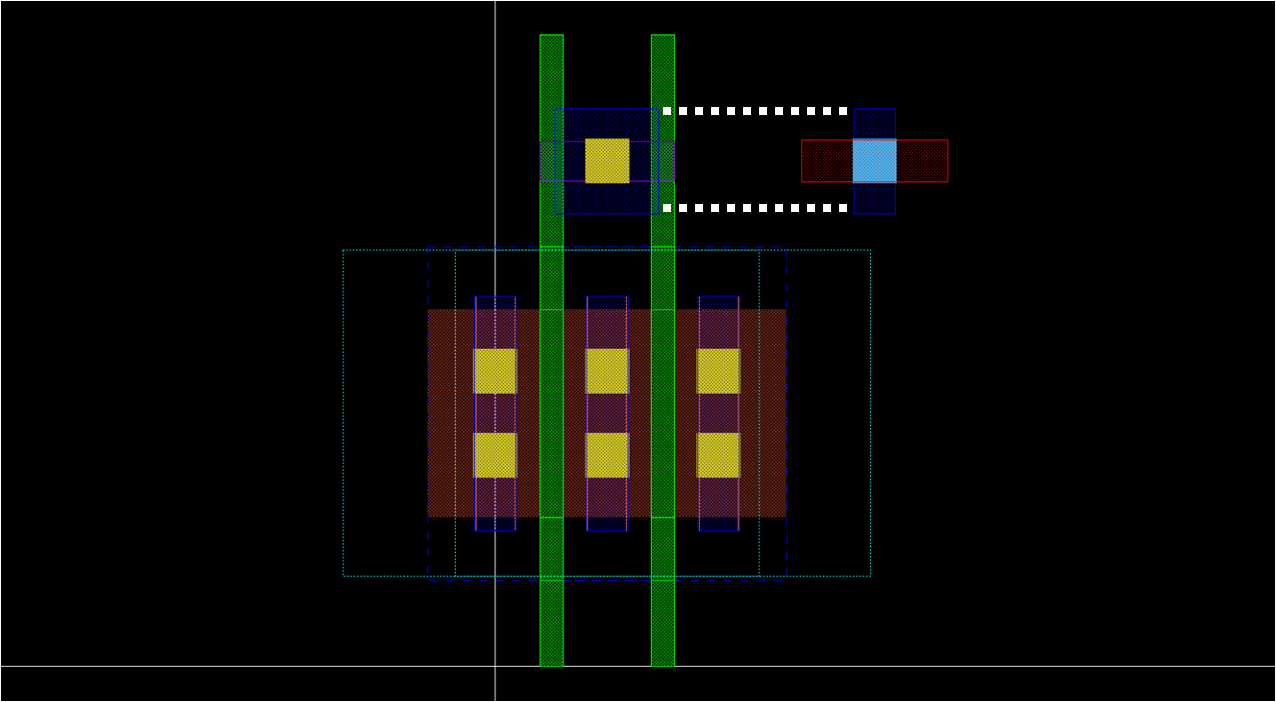

- Draw additional M1 rectangle

- To meet minimum area requirement for M1

- and to avoid ‘+’ shape when a M1_M2 via is placed

- Again, note that it will be placed in array

template

template

- Draw some layers (technology dependent)

- Draw some other layers such as finfet and CPO if needed, refer related options embedded in pcell

- Attach pin/label on M1

- Draw M1 pin or label layer on existing M1 drawing layers

- On gate and every source/drain

- Choice of pin/label layer depends on technology

- Attach label at the middle of each pin/label layer

- S0, D0, S1, and G0

template

template

- You can specify the pin area with a rectangle of [M1, pin] and net name with a label of [M1, pin]

- Optionally, you can specify the pin name with a label of [text, drawing]. This is useful if you want to assign multi pins for same nets.

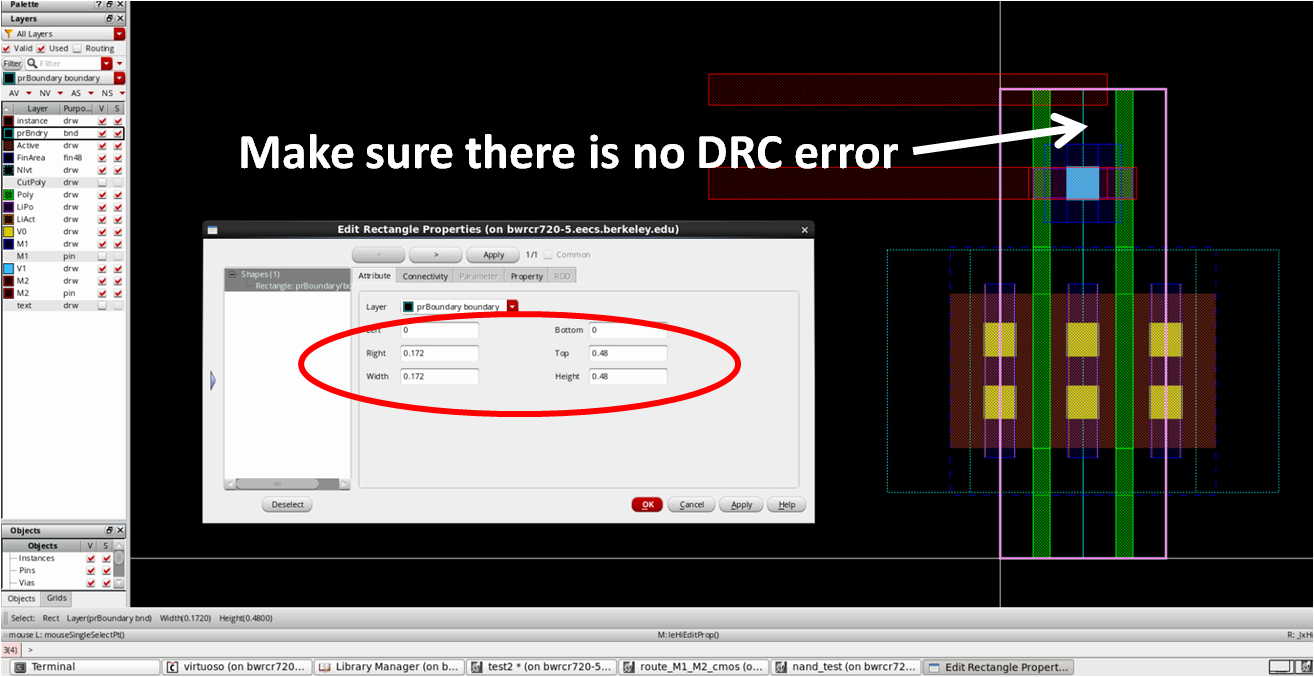

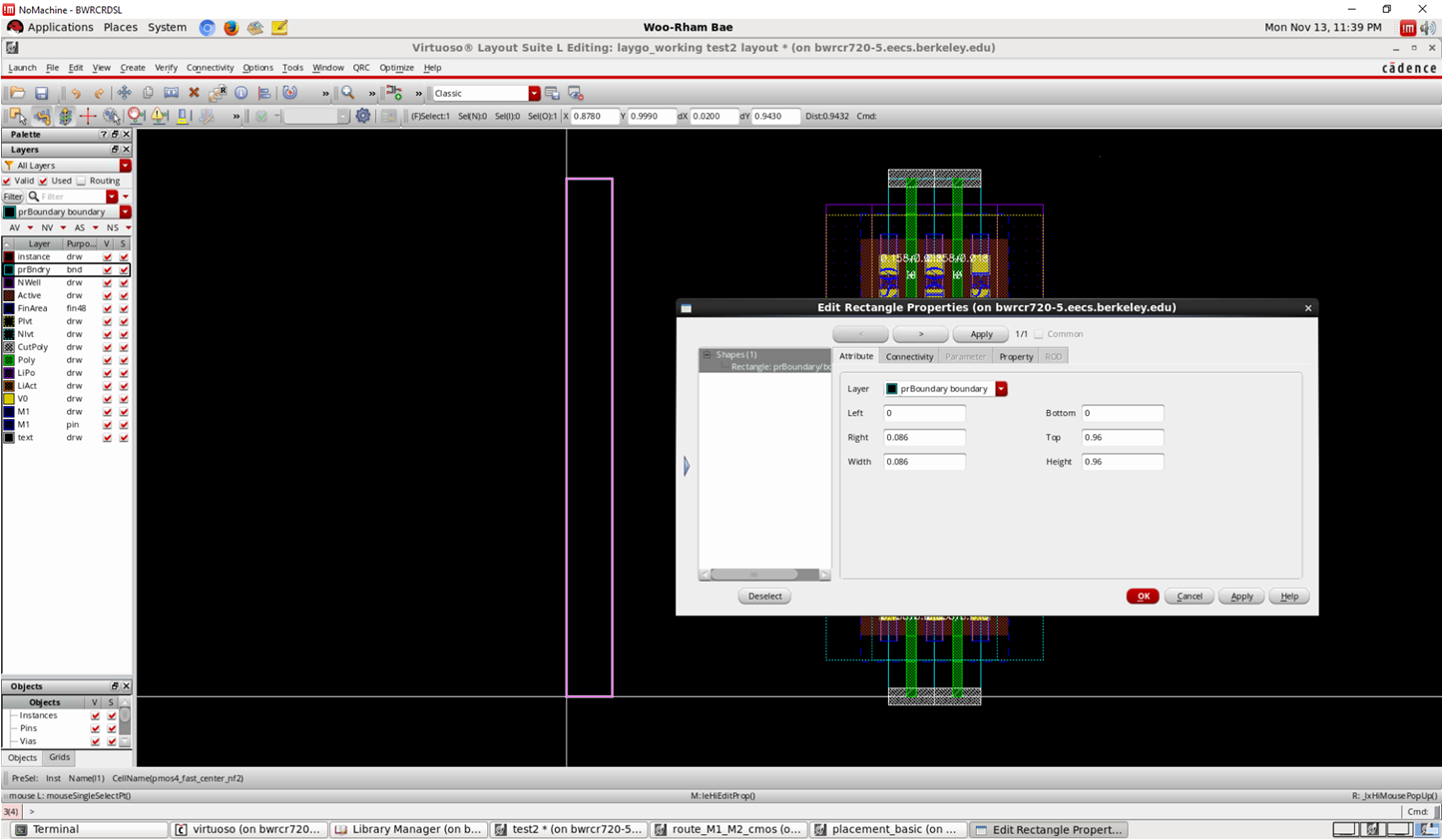

- Set boundary

- Use prboundary layer (or corresponding layer) to define the placement boundary of the cell

- Note that one M2 routing will be placed at the top

template

template

- It is recommended to set the height of the template as a common multiples of variety of numbers (i.e. 0.48um, 0.6um…)

- To be compatible with all the routing grids, all placement will be done based on prboundary!

template

template

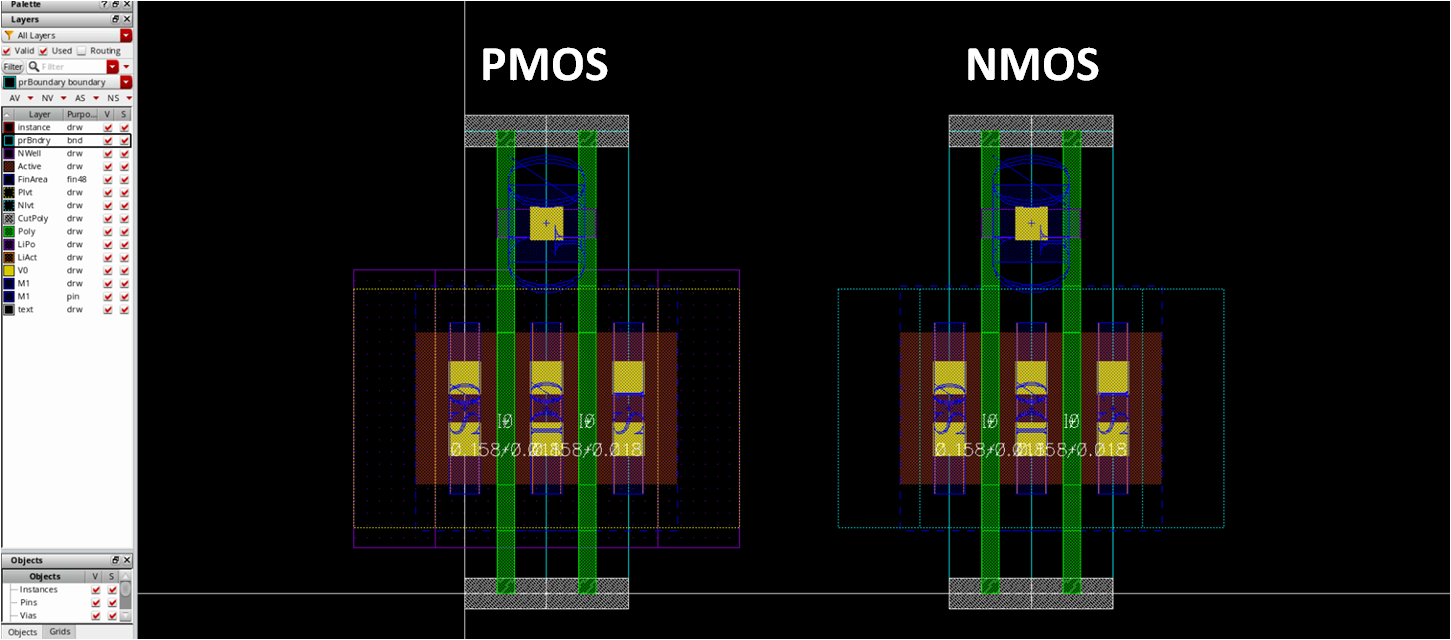

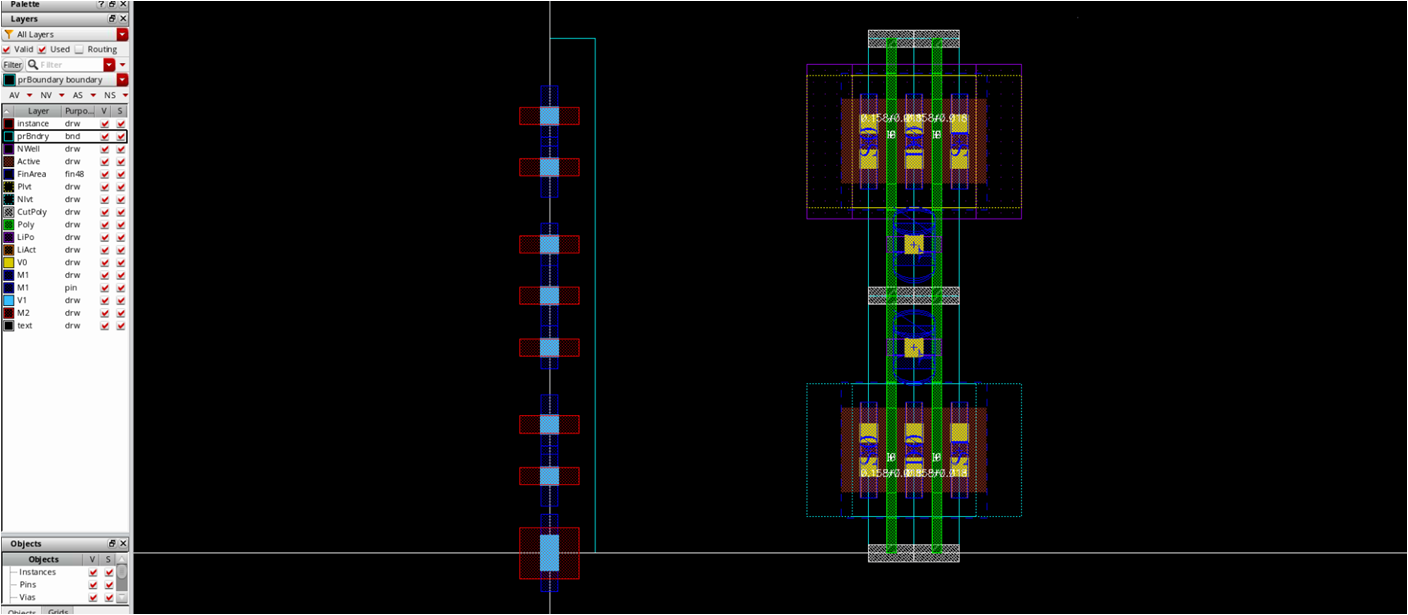

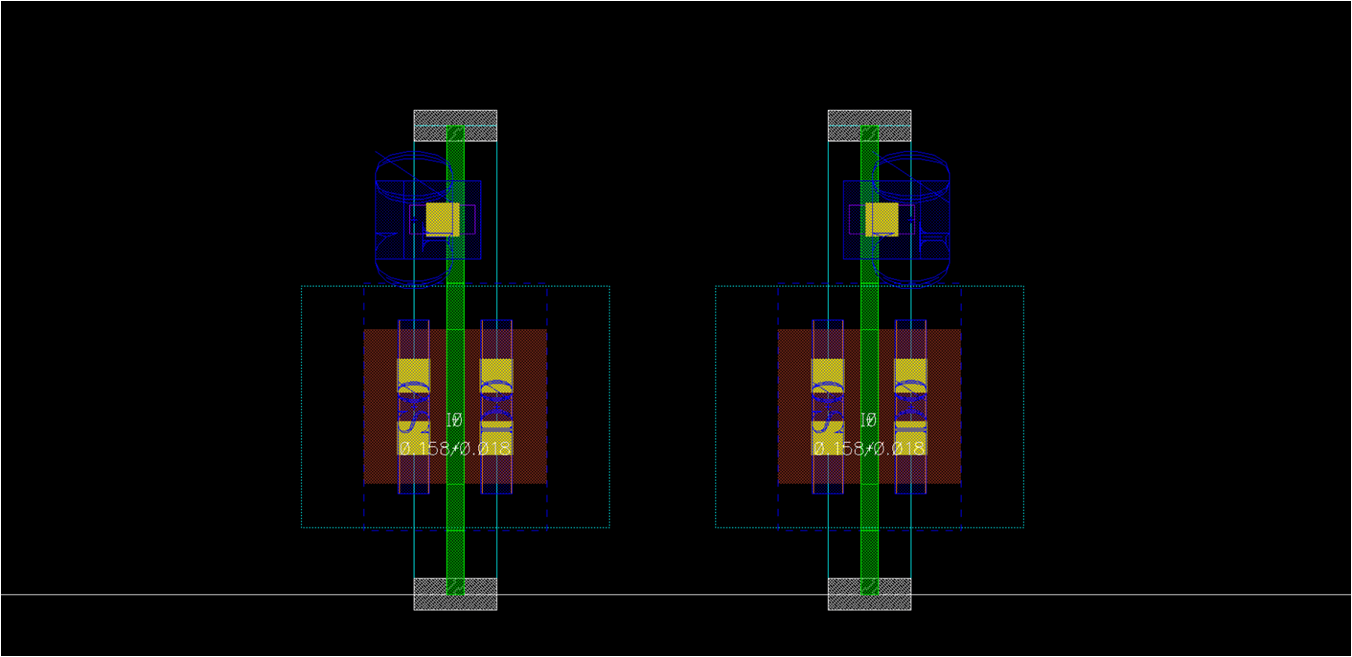

- Draw pmos4_fast_center_nf2

- It should be very easy if you have drawn nmos4_fast_center_nf2

template

template

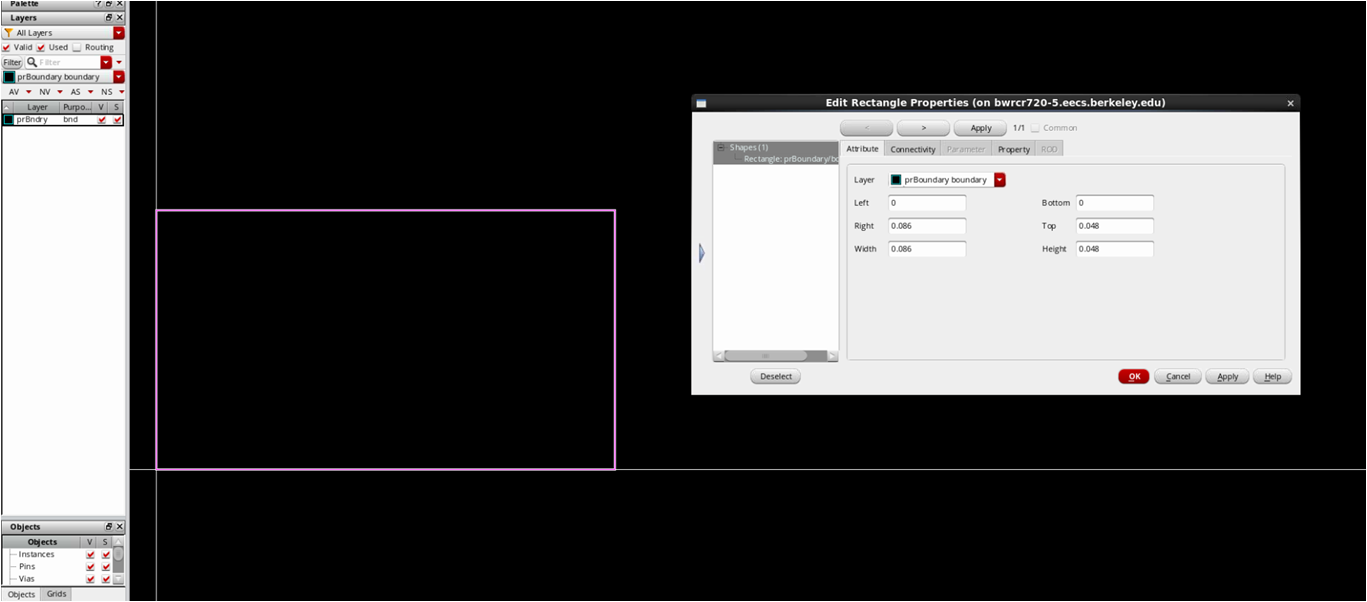

- Draw placement_basic

- There is only a prboundary rectangle

- xy0 = (0,0), xy1 = (poly pitch, one of divisions of height of nmos_fast_center_nf2)

- All x coordinates should be multiples of poly pitch

template

template

Routing grids¶

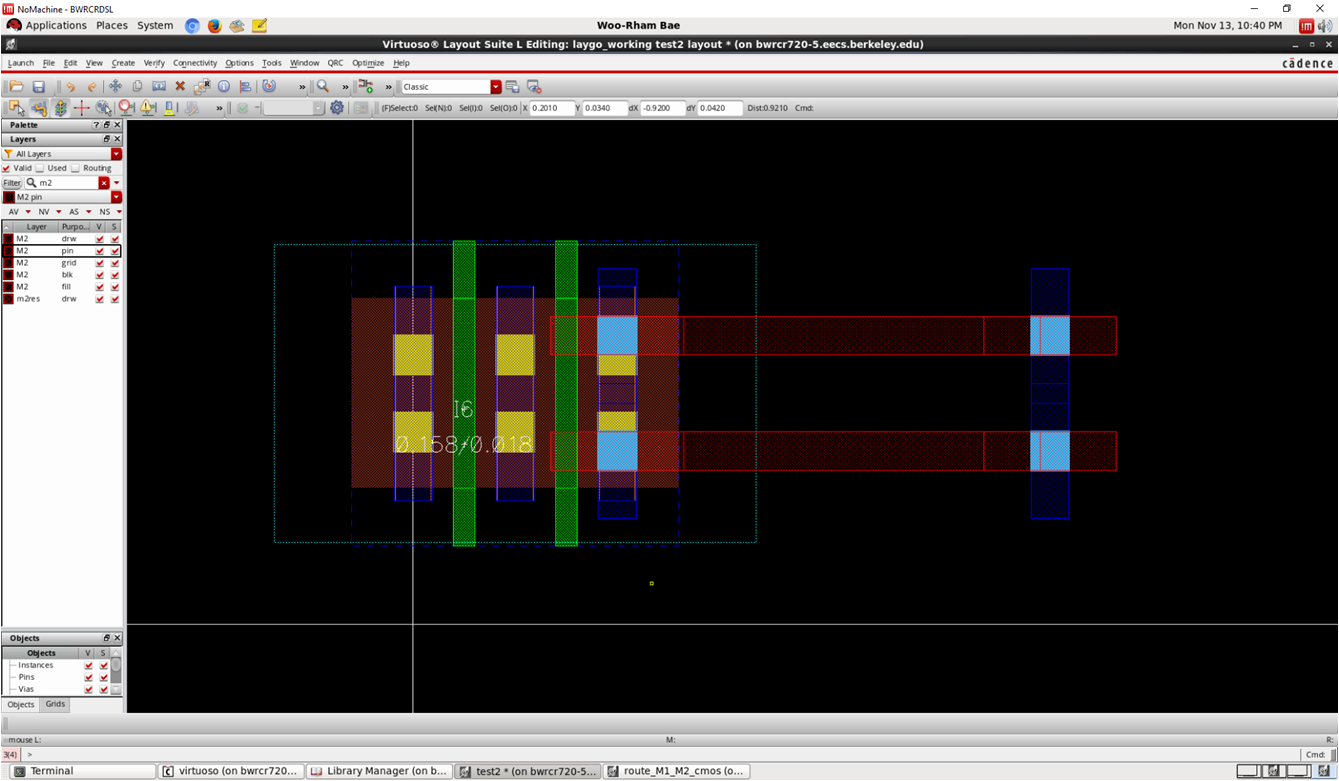

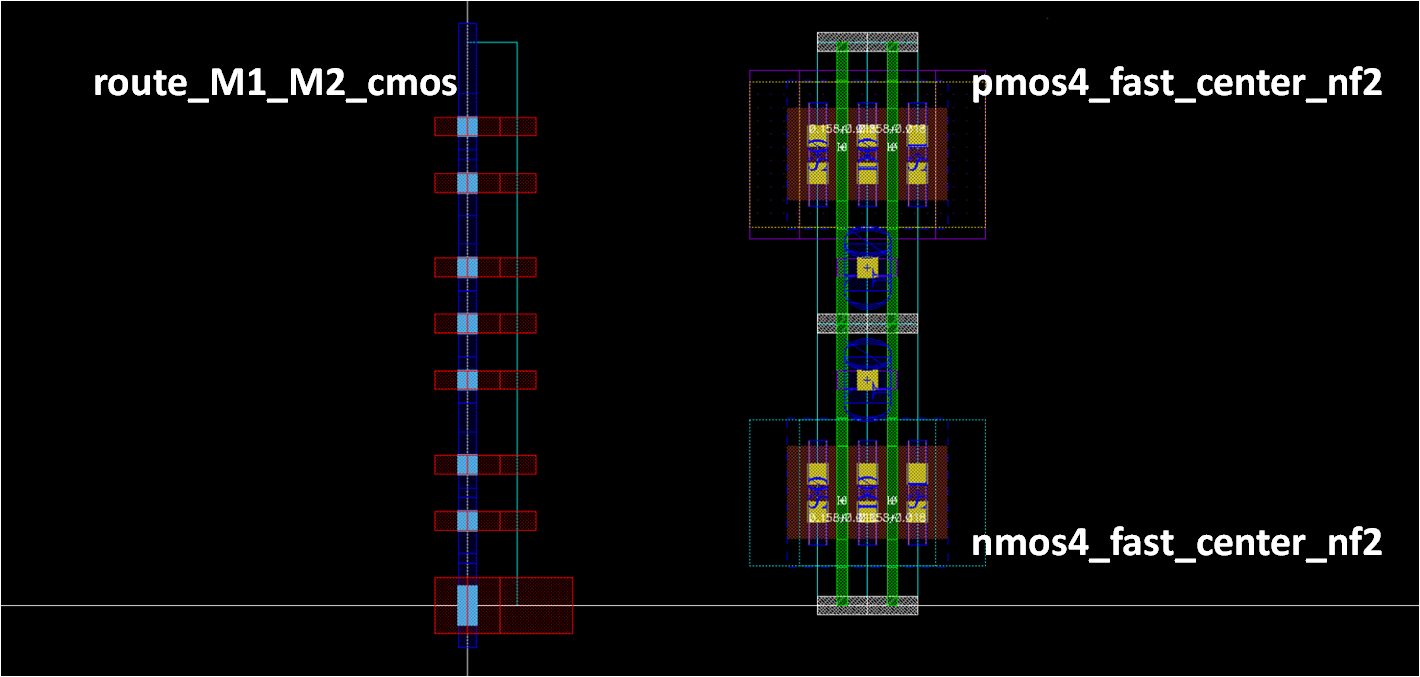

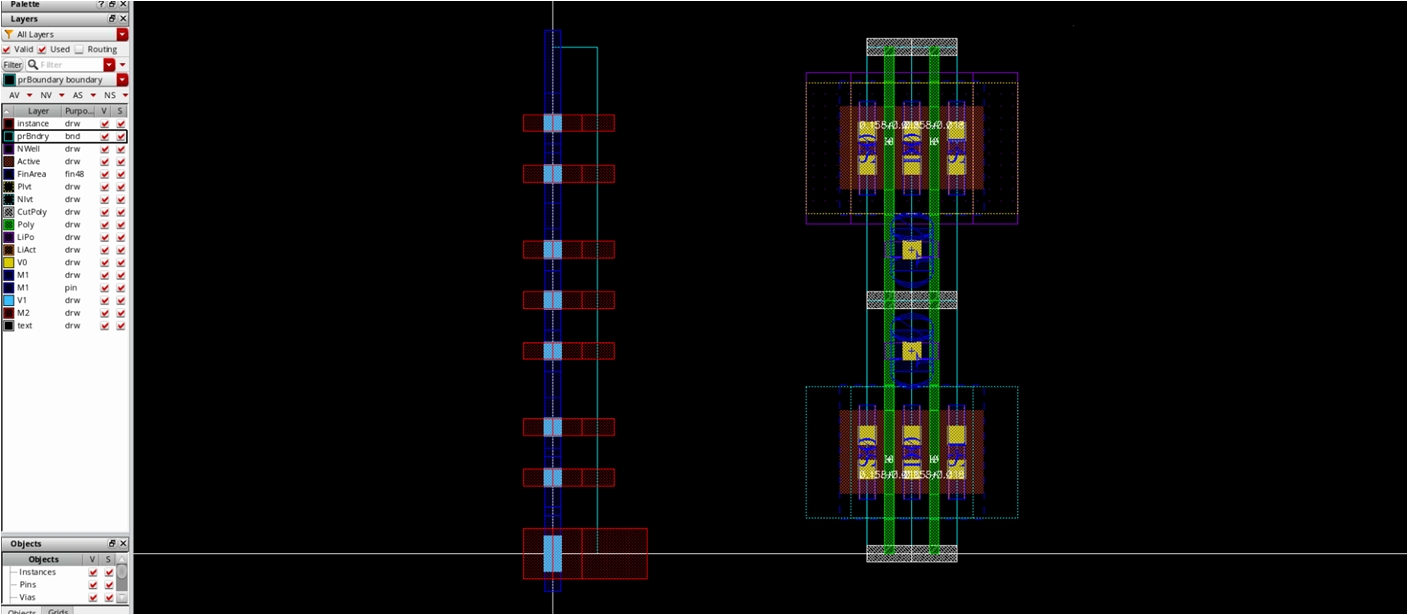

Draw route_M1_M2_cmos

- Most important routing grid

- Before drawing that, place nmos and pmos templates

template

template

- 8 horizontal routings within the CMOS template

- 1 for VDD/VSS rail, 2 for NMOS S/D, 2 for PMOS S/D, 2 for CMOS gate, and 1 for additional gate routing

template

template

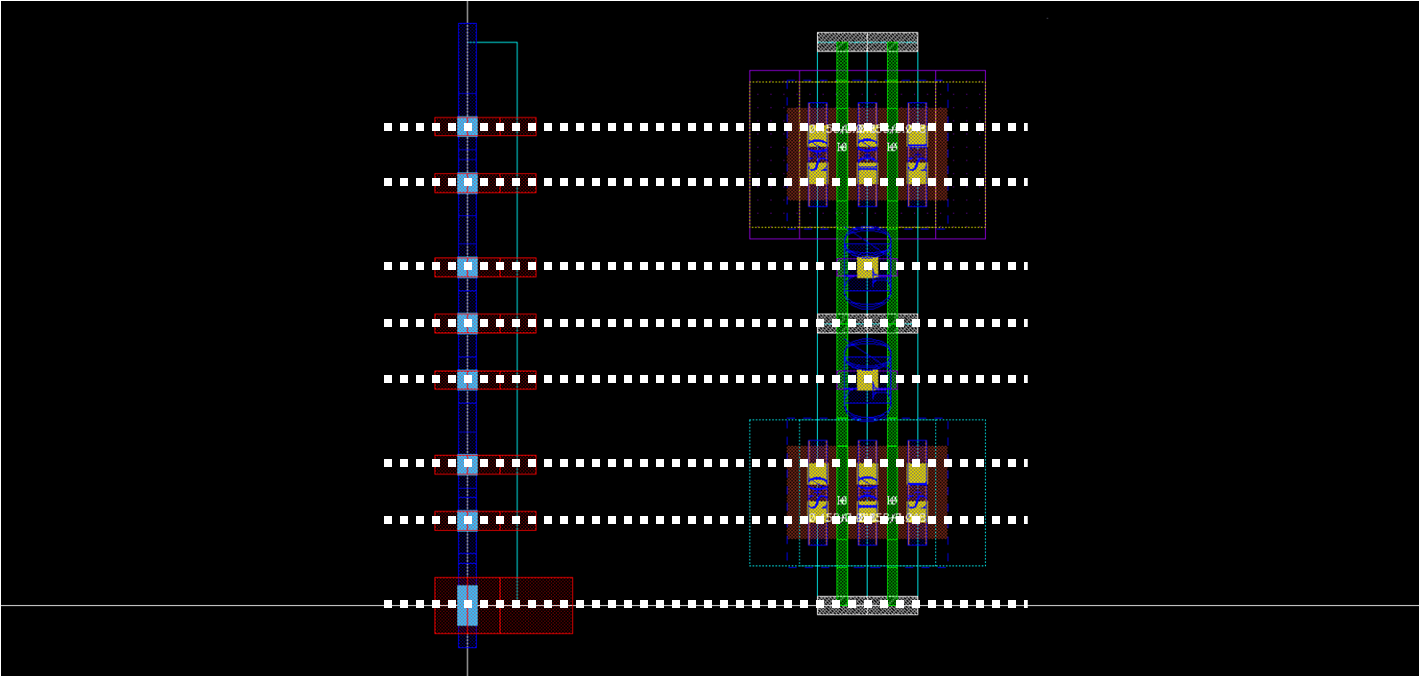

- Draw prboundary

- xy0 = (0,0), xy1 = (poly pitch, height of cmos)

template

template

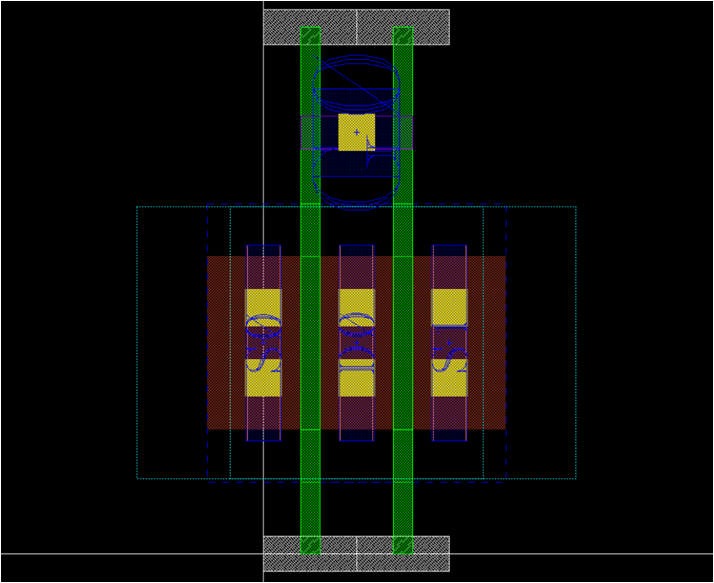

- Place M1_M2 vias

- x=0 for all vias, so what you have to do is to set y

- We have already considered that when we drawn nmos, so we can easily find proper y coordinates

template

template

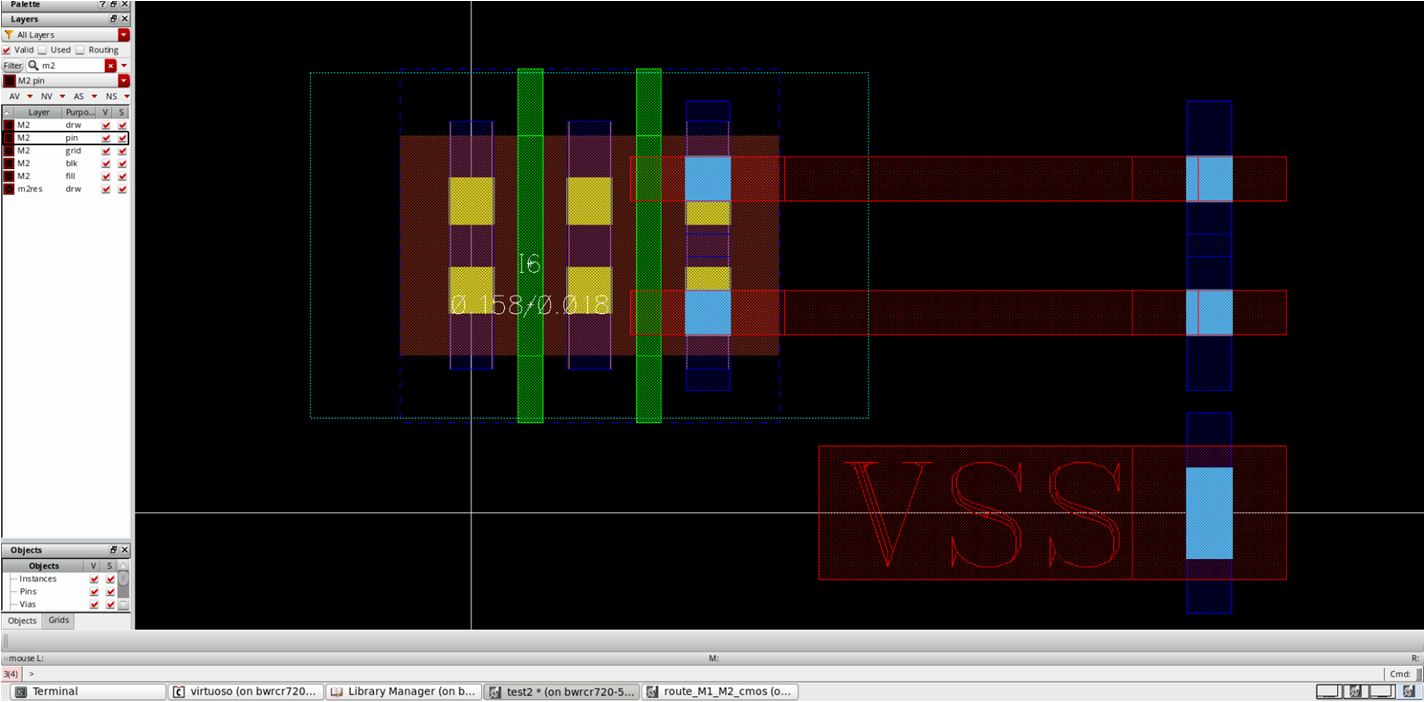

- Draw M1/M2 wires

- Make sure your routing grid is compatible with CMOS template

- After that, delete nmos/pmos templates

template

template

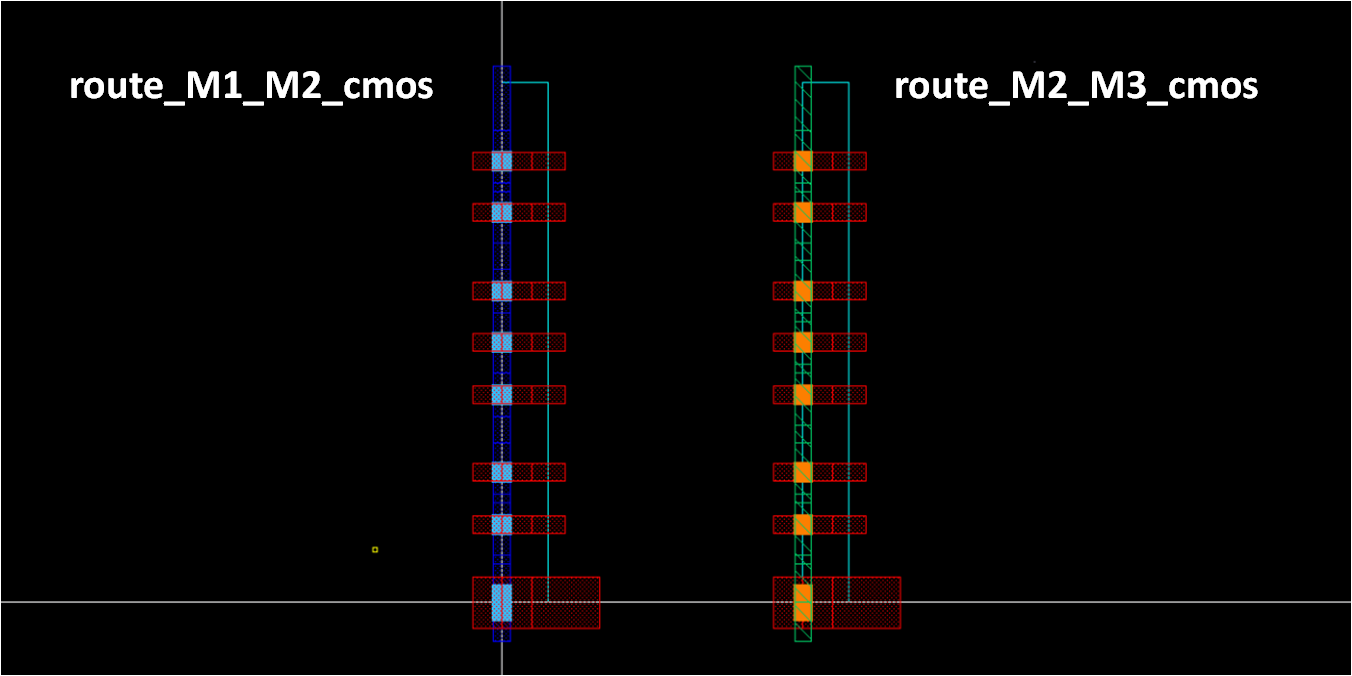

- Draw route_M2_M3_cmos

- CMOS-compatible M2_M3 grid is also required

- Just modify M1_M2 vias and M1 rectangle with M2_M3 vias and M3 rectangle from route_M1_M2

template

template

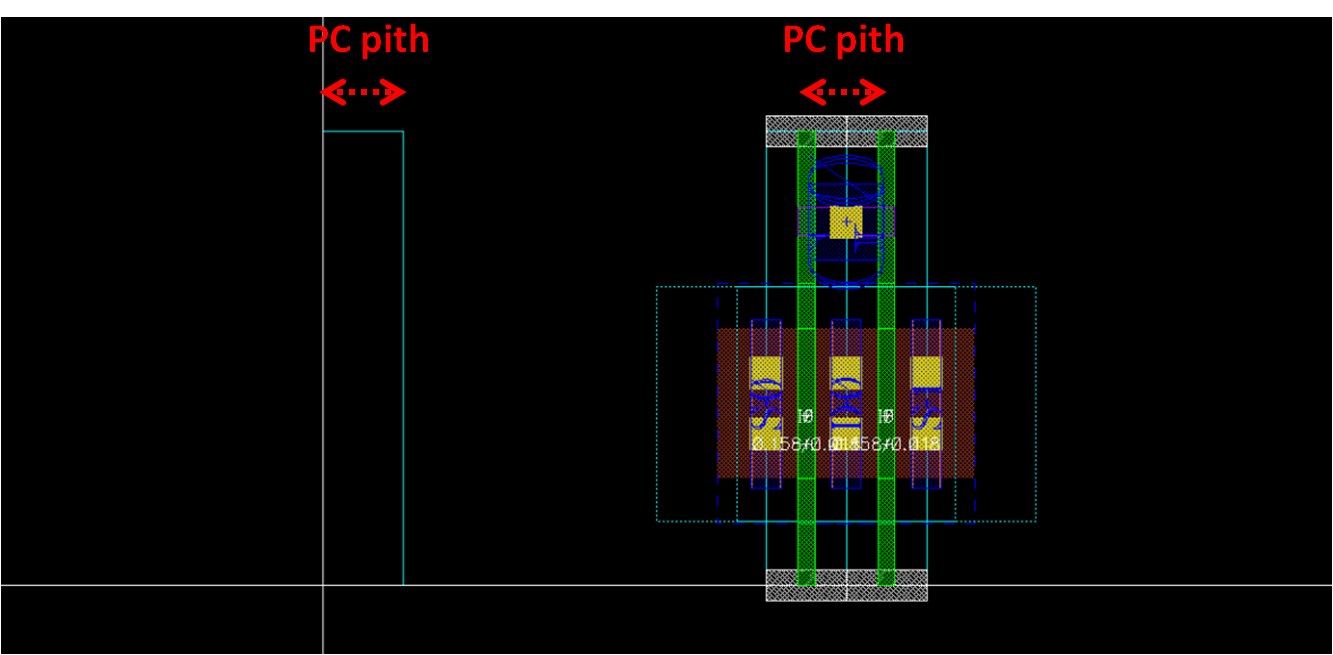

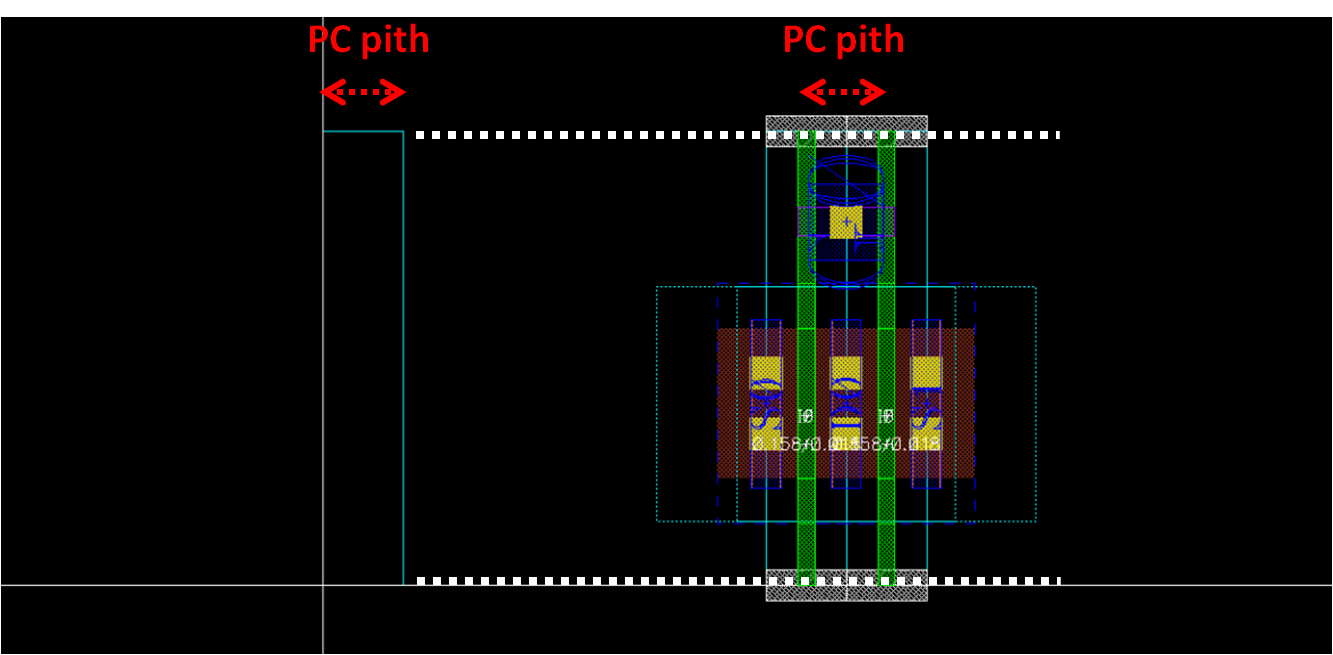

- Define rest of routing grids

- Draw prboundary: if min. pitch of vertical layer is narrower than PC pitch, x=PC pitch

- else, x=N x PC pitch, where N x PC pitch > min. pitch

template

template

- When we define y grid, we have to consider spacing rule for horizontal layer and height of MOS template

- So basically, y of prboundary is height of MOS

template

template

- After that, all the horizontal routing grid within prboundary should be defined as follows

template

template

- However, if y grid is one of divisions of height of MOS and also meets the spacing rule, a simple template shown below is sufficient

template

template

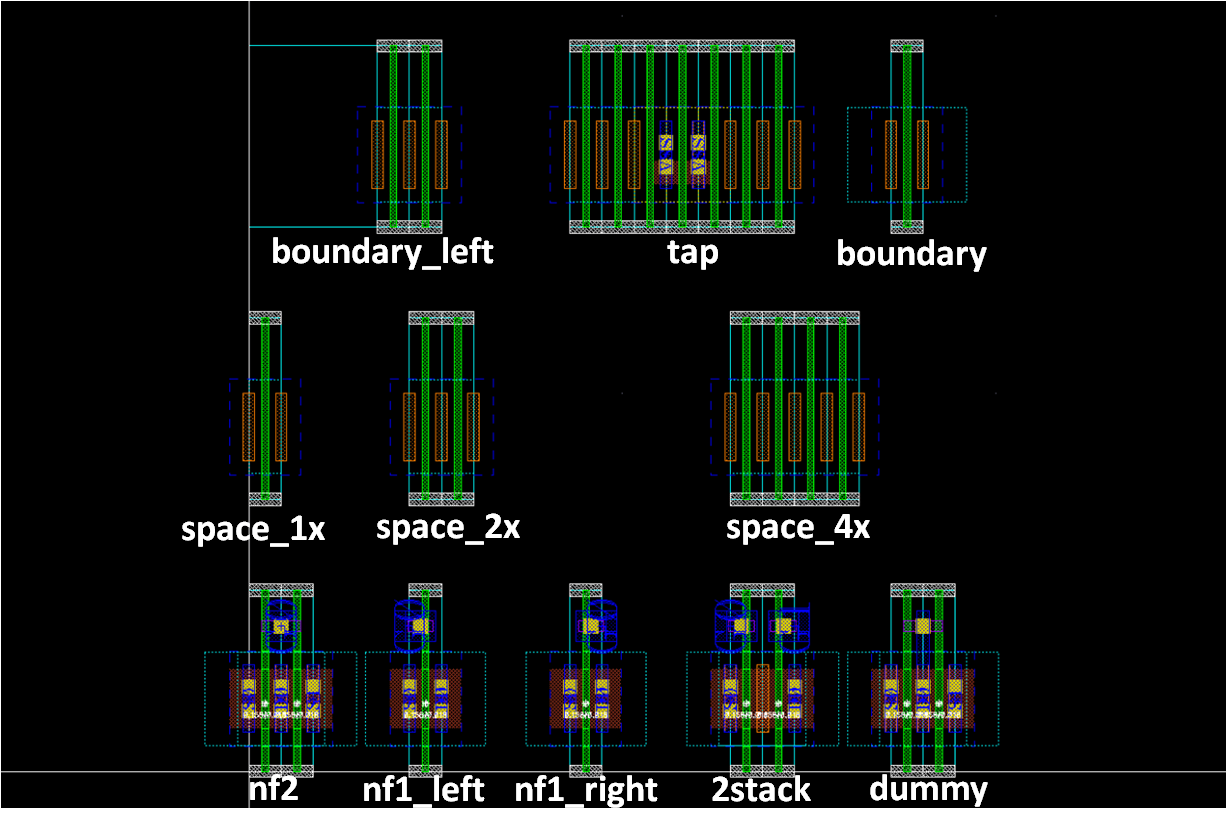

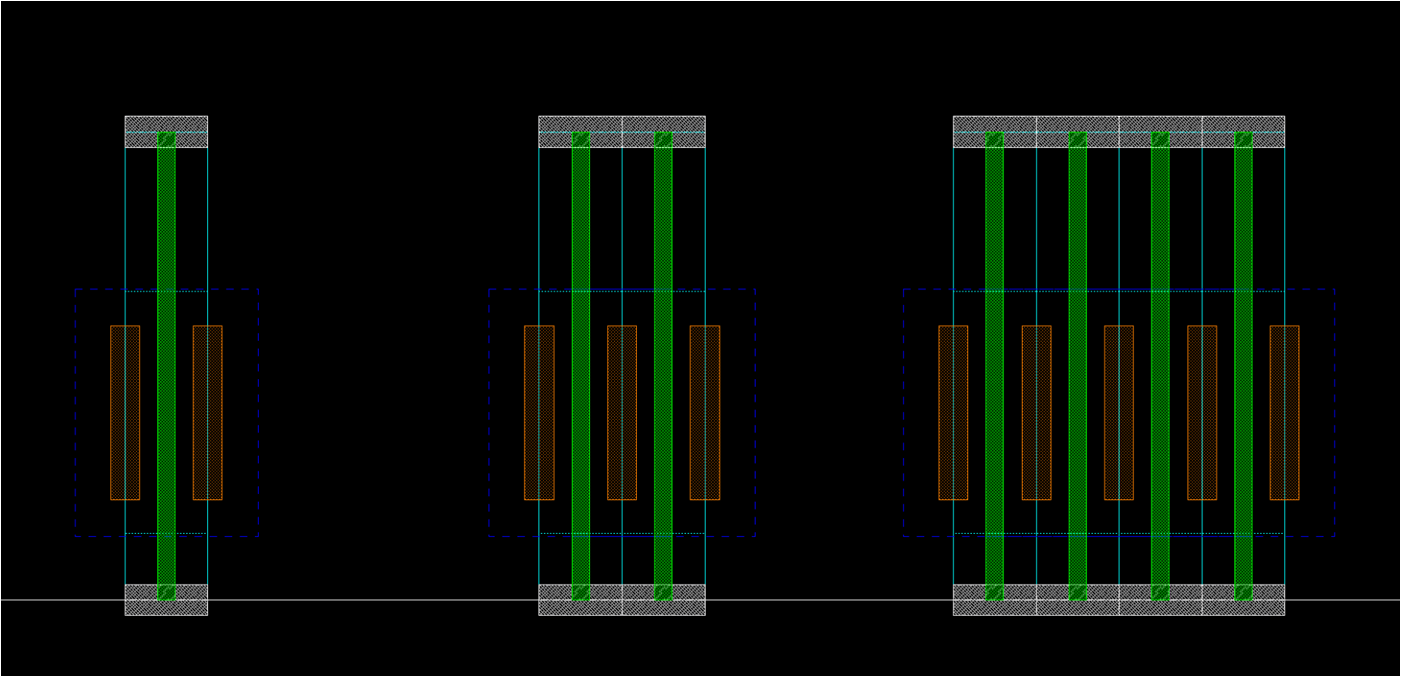

Draw rest of transistor templates¶

- nf1, stack, dummy, filler, boundary, and tap

template

template

- nf1

- nf1_left and nf1_right according to the direction of gate contact

- Consider DRCs for gate connection

template

template

- 2stack

- Used for NAND_1x, TINV_1x…

- Utilize gate connection technique you found in nf1 template

template

template

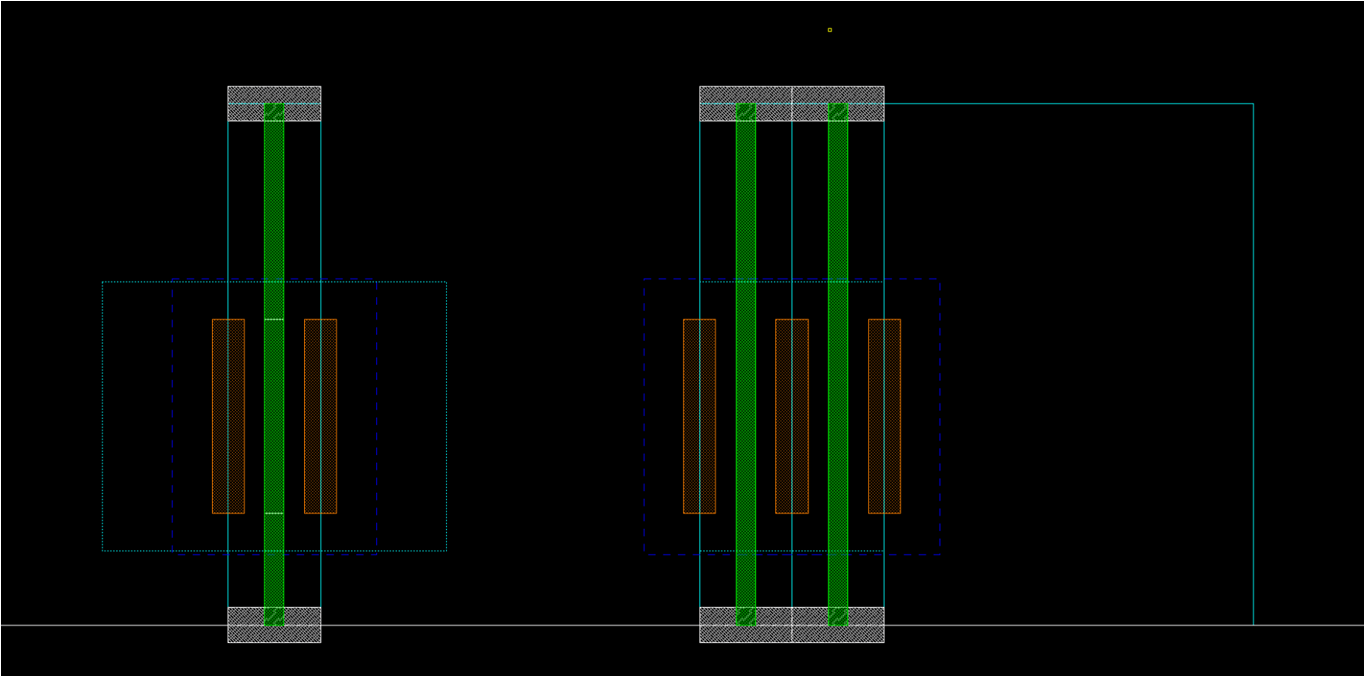

- Dummy

- Use center_nf2 template

- Just connect gate-drain and remove pin on the gate

template

template

- Space

- For filling space

- Note that RX layer might be included in 4x cell, in order to satisfy RX density rule (not in this layout)

template

template

- Boundary

- Usually, nmos_fast_boundary == space_1x

- boundary_left/right should resolve design rules regarding poly dummy

template

template

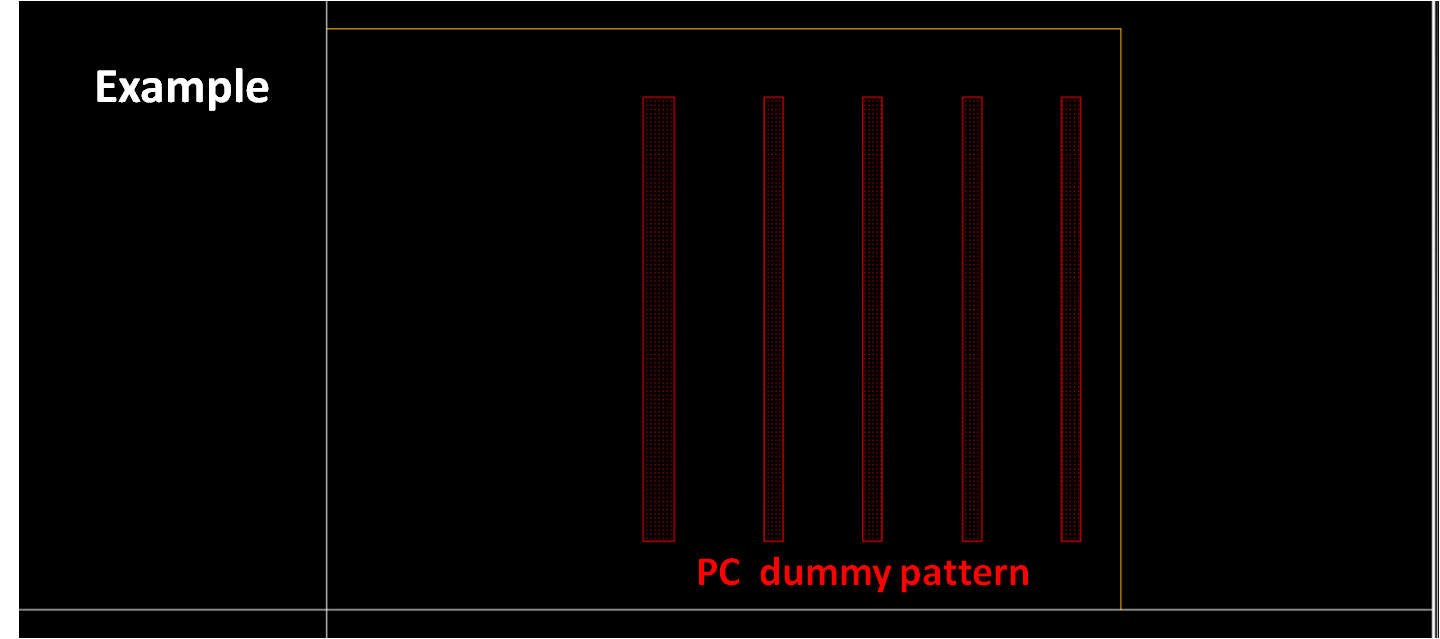

- Number and pattern of poly dummy depends on technology

- Refer dummy option in pcell

template

template

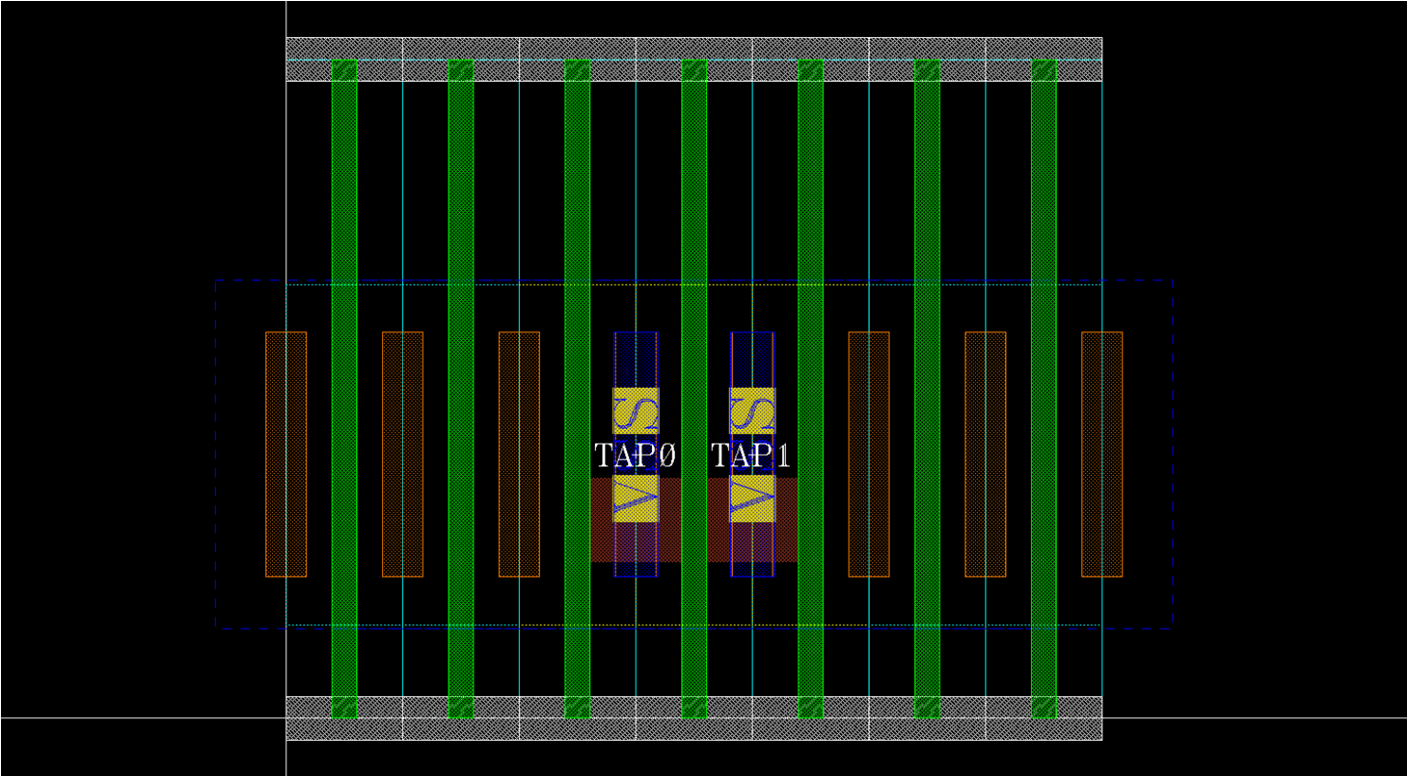

- Tap

- For connecting body to VDD/VSS

template

template

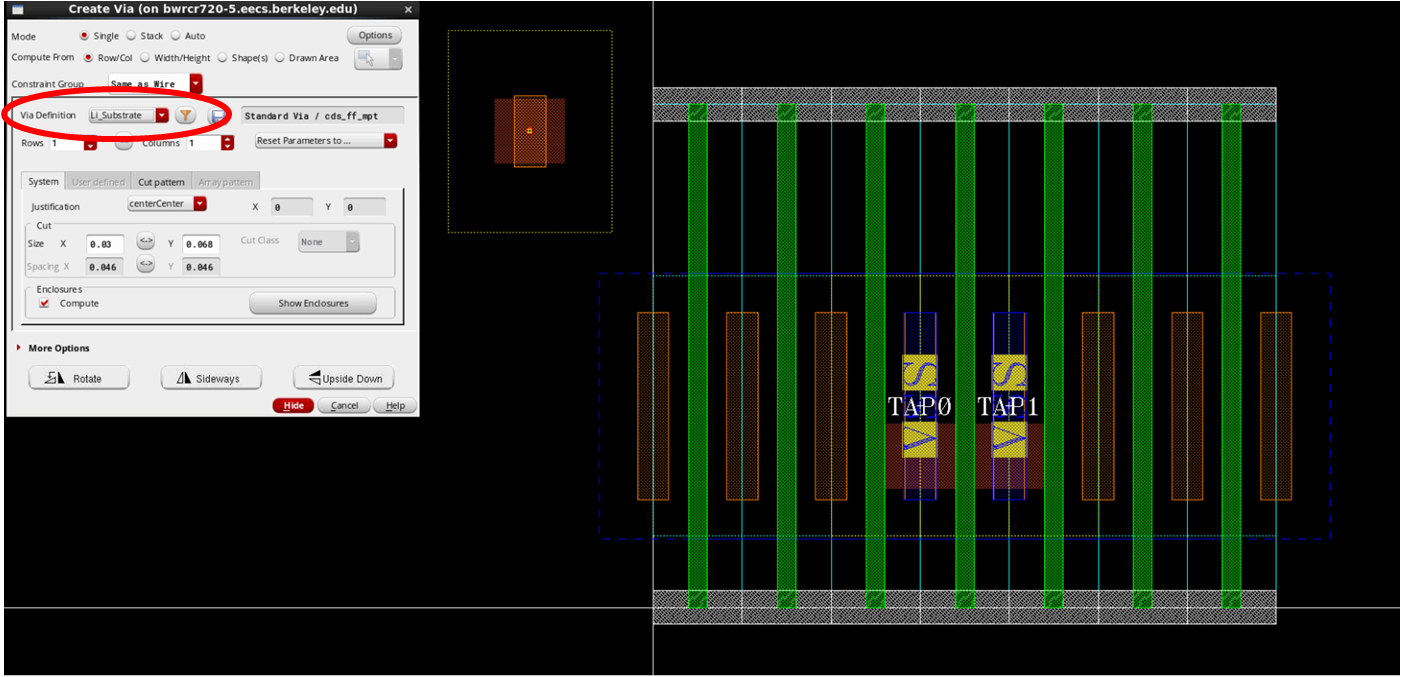

- Refer to psub/nwell contact provided by foundry

- Create => Via => Via Definition

template

template

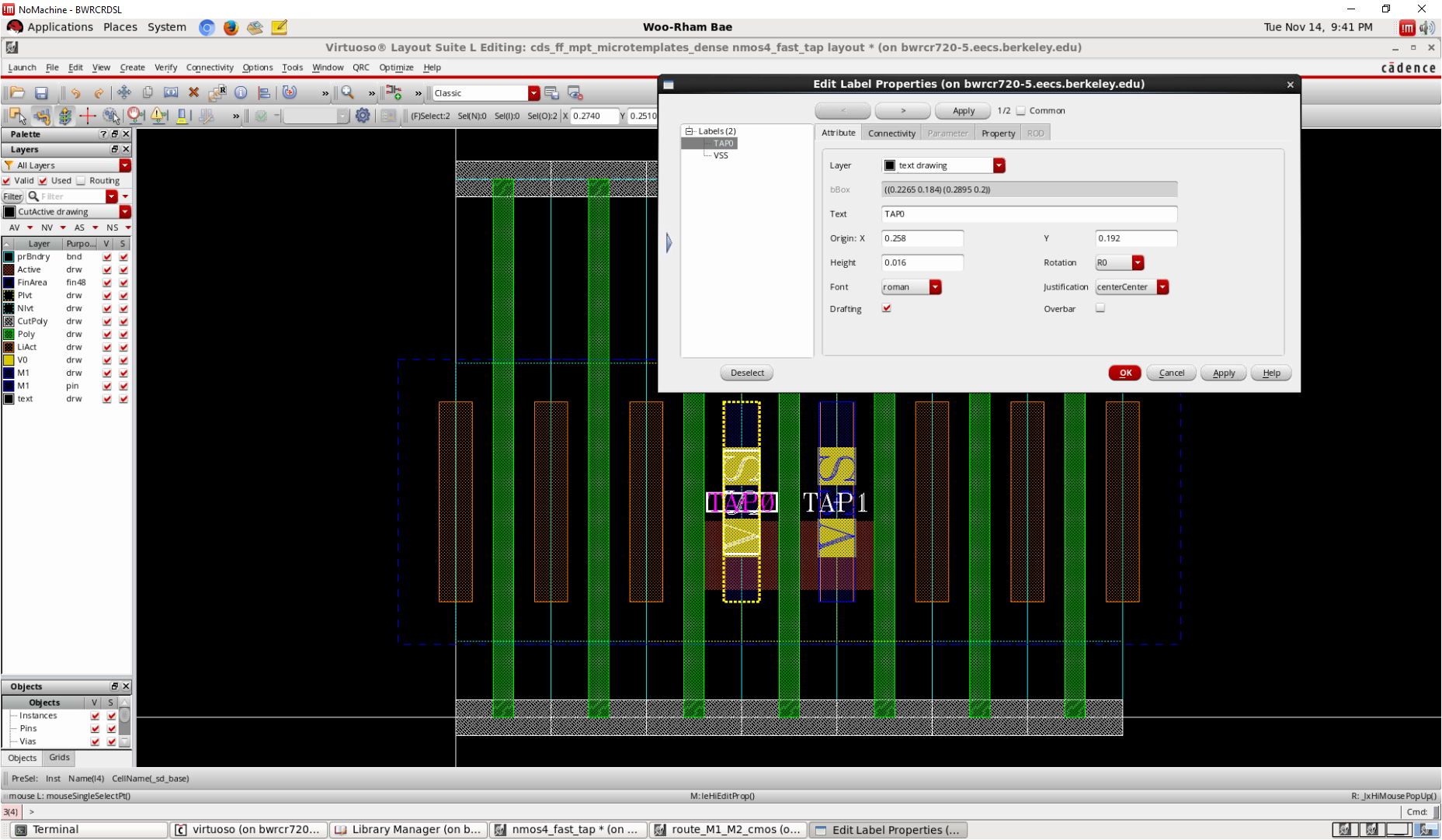

- Two M1s in tap cell

- VSS M1-pin to both of them

- TAP0/TAP1 pin using text drawing

template

template